EDM Manufacturing vs CNC Milling – The global precision engineering machines market has been rapidly growing, with a market size estimated at $13.07 billion in 2022 and projected to reach $13.90 billion in 2023. This staggering statistic highlights the increasing importance of precision manufacturing in various industries, ranging from aerospace to medical devices.

Two techniques are often pivotal in realizing intricate designs and ensuring accurate measurements. These are electrical discharge machining (EDM) manufacturing and the production of CNC machined parts using computer numerical control, particularly CNC milling.

In this post, we’ll delve into these two manufacturing processes, understand their differences, and help you make informed decisions for your specific project requirements.

Table of Contents

Understanding EDM Manufacturing

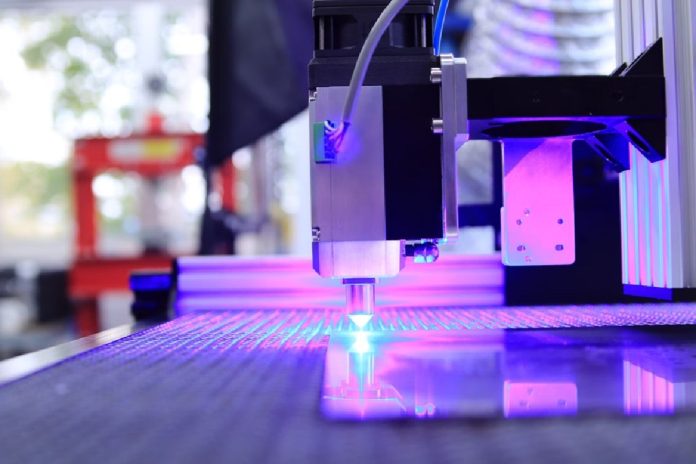

Electrical discharge machining, as the name suggests, is a precision manufacturing process that uses electrical discharges to remove material and shape the desired part. The EDM process involves creating controlled sparks between an electrode and the workpiece, eroding the material and creating the desired shape. Essentially, there are two main types of EDM processes: wire EDM and sinker EDM. Wire EDM uses a thin wire as the electrode, while sinker EDM uses a shaped electrode to create cavities.

EDM manufacturing finds applications in various industries, including aerospace, automotive, and tool and die making. It’s particularly useful when working with hard materials such as hardened steel or exotic alloys. One of the key advantages of EDM is its ability to produce intricate shapes and fine details with high precision. However, the process is relatively slow, and the surface finish may require additional post-processing.

Understanding CNC Milling

CNC milling, also known as computer numerical control milling, is a versatile machining process that utilizes computer-controlled machines to remove material from a workpiece. The process involves rotating cutting tools that gradually remove material to create the desired shape. CNC milling machines come in two main types: vertical mills and horizontal mills, each with their specific advantages and applications.

CNC milling is widely used in industries such as automotive, aerospace, and manufacturing. It offers excellent precision and accuracy, making it suitable for producing complex parts with tight tolerances. CNC milling is able to handle a wide range of materials, including metals, plastics, and composites. It provides faster production times compared to EDM, making it an ideal choice for high-volume manufacturing.

Key Differences between EDM Manufacturing vs CNC Milling

EDM manufacturing and CNC milling are both precision machining processes, but they cater to different requirements. EDM stands out in delivering intricate shapes with high precision, perfect for complicated geometries and nuanced details. CNC milling, while precise, might struggle with extremely detailed shapes. When it comes to materials, EDM is versatile, working effortlessly with hard and heat-treated alloys. In contrast, CNC milling can process a diverse array of materials, but harder substances might necessitate specialized tooling.

For parts boasting complex geometries, sharp corners, or challenging internal features, EDM is the go-to option. CNC milling is also proficient with complex designs, yet it might stumble with certain intricate internals. Another differentiating factor is the finish; EDM typically results in a rougher surface, often necessitating further polishing or grinding. CNC milling produces a smoother finish, largely bypassing the need for extensive post-processing.

From a financial perspective, EDM’s specialized equipment and extended processing times can inflate costs. CNC milling, with its quicker production, often proves more economical, especially for bulk production. Thus, while CNC milling shines in projects demanding speed or high volumes, EDM’s unparalleled precision makes it ideal for prototyping or low-volume production.

Choosing the Right Manufacturing Process

Selecting the appropriate manufacturing process depends on several factors, including project requirements and budget constraints. Consider the complexity of the part, desired precision, material properties, required surface finish, production volume, and time constraints.

For projects that demand intricate shapes, fine details, and high precision, EDM manufacturing is a viable option. It excels in producing complex parts and is ideal for low-volume production or prototyping. On the other hand, CNC milling is suitable for projects that require excellent precision, faster production times, and higher production volumes.

To make an informed decision, it’s crucial to collaborate with manufacturers and experts in the field. They can provide valuable insights based on their experience and guide you in selecting the most appropriate manufacturing process for your specific needs.

Final Thoughts

EDM manufacturing and CNC milling are two popular precision machining processes with distinct characteristics. Understanding the differences between them is crucial for making informed decisions when it comes to choosing the right manufacturing process for your project.

Consider factors such as precision requirements, material compatibility, complexity of part features, surface finish, cost considerations, and production volume. By collaborating with experts and evaluating your project requirements carefully, you can ensure the successful realization of your designs in the most efficient and cost-effective manner. Embrace the power of precision manufacturing and unleash the potential of your projects.